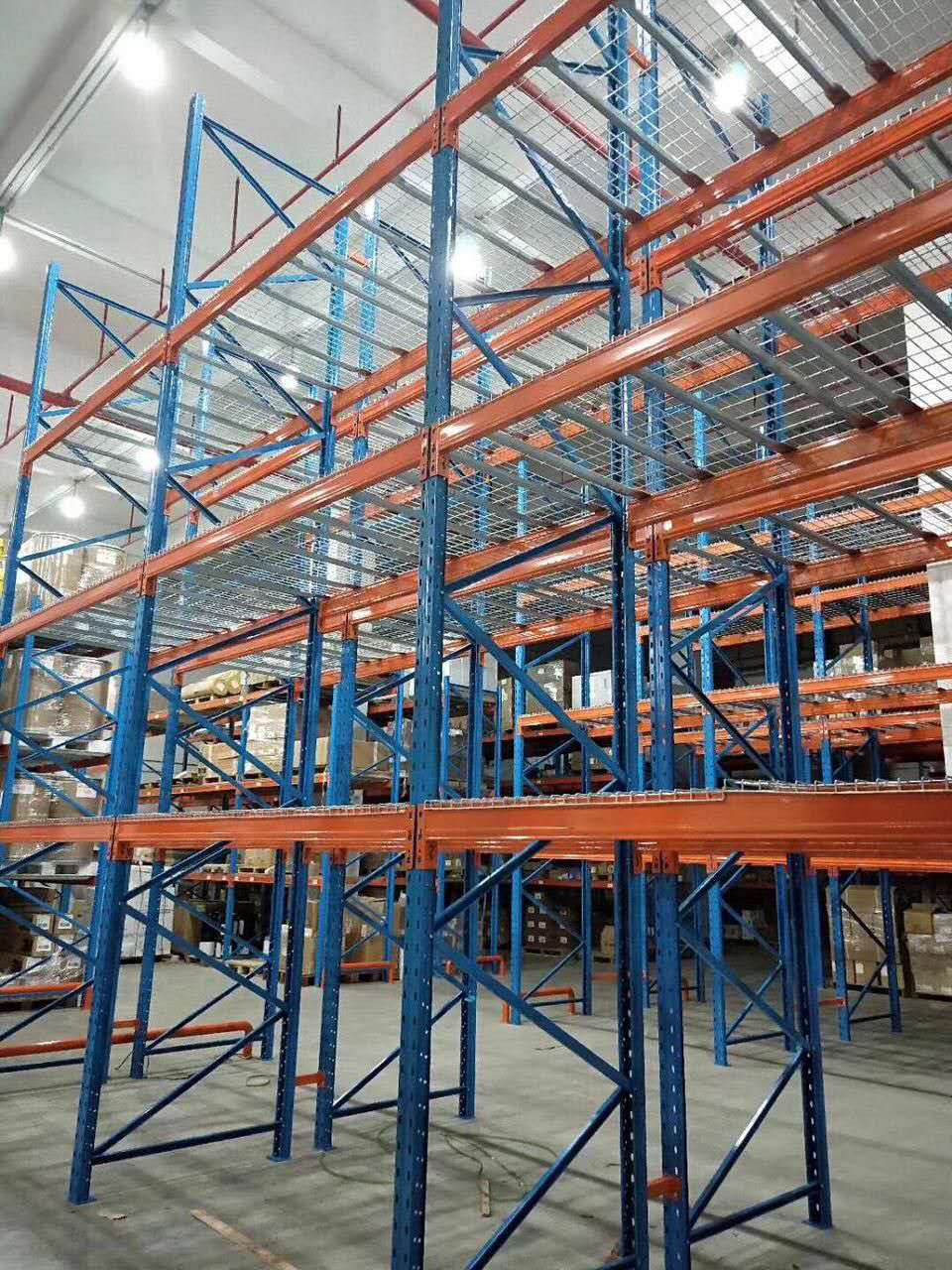

Pallet racking

Heavy duty rack also named beam rack, It is very common in the various kinds or the warehouse racks. The main components are upright frame+beam, structure is concise and effective. This is most diversified warehouse rack, works with forklift for pallet up and down. It is wildly use for most of the enterprises.

Additional information

| L*D*H (mm) | 2700*1000*4500(most common), Customizable |

|---|---|

| Color | Blue, Customizable, Orange |

| Layer | 3layer, 4layer, 5layer, Customizable |

| Load Capacity | 1000kg, 2000kg, 3000kg, Customizable |

| MOQ | 10 sets |

| Weight | about 125-155 kg |

| Volume | 0.30CBM |

| Estimated Delivery Time | 10-15 days |

Free design drawings for you

Layout plan

Three-dimensional view

Renderings

The main production process of Pallet racking

1

Punching Process

Punches run the length of the hanging plate at standard intervals where the cross beams are connected, most of them are 50mm or 75mm pitch.

2

Rolling Process

Steel coil through the rolling equipment to form the upright and beam, beam usually have P beam and interlock beam, upright usually have diamond hole and teardrop hole.

3

Welding Process

Through welding, the hanging plate and beam; upright and footplate are closely connected together, which effectively strengthens the stability of the rack structure.

4

Spraying And Baking Process

Polish the product after welding, then use electrostatic powder spraying technology on the surface, and finally use the high-temperature baking process to ensure a smooth surface.

5

Packaging Process

Finally came to the last step. After the production of the product is completed, we usually package the exported goods to avoid long-distance transportation damage and seawater erosion during shipping.

Our products are packaged in the following ways

Air Bubble Film

Pallet Packaging

Wooden Case

Carton Box

Installation of Pallet racking

Heavy duty rack wildly use many manufacturer, E-commerce warehouse, third logistic and distribution center etc.It is suitable for many kinds of small bulk items, but also suitable for a small variety of items.