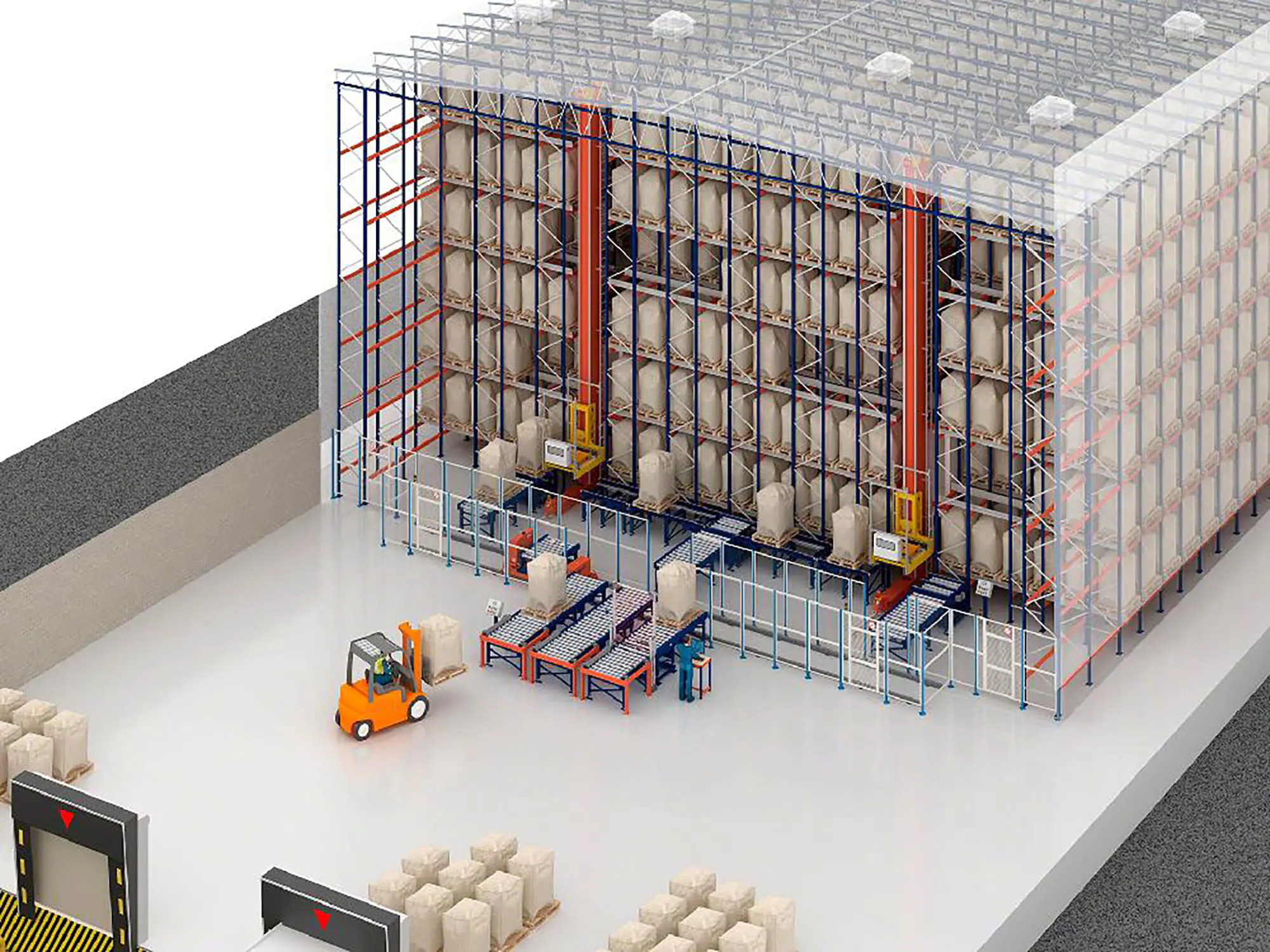

AS/RS

Automated (AS&RS) Rack Warehouse Solution were grouped by rack system, logistics system,Electrical control system and Tunnel stacking forklift. Automated warehouse rack adopt the top-ranking integration logistic concepts, through the following cooperated operation: advance control, highway, communication and information technology for finish the cargo destined self-motion, fast and accurate, high efficient unloading.

Additional information

| L*D*H (mm) | Customizable |

|---|---|

| Layer | 5layer, 6layer, 7layer, Customizable |

| Load Capacity | 100kg, 200KG, Customizable |

| Weight | Customizable |

| Volume | Customizable |

| Color | Blue, Customizable, Orange |

| MOQ | 20 sets |

| Estimated Delivery Time | 25days |

Free design drawings for you

Layout plan

Three-dimensional view

Renderings

The main production process of AS/RS

1

Punching Process

Punches run the length of the hanging plate at standard intervals where the cross beams are connected, most of them are 50mm or 75mm pitch.

2

Rolling Process

Steel coil through the rolling equipment to form the upright and beam, beam usually have P beam and interlock beam, upright usually have diamond hole and teardrop hole.

3

Welding Process

Through welding, the hanging plate and beam; upright and footplate are closely connected together, which effectively strengthens the stability of the rack structure.

4

Spraying And Baking Process

Polish the product after welding, then use electrostatic powder spraying technology on the surface, and finally use the high-temperature baking process to ensure a smooth surface.

5

Packaging Process

Finally came to the last step. After the production of the product is completed, we usually package the exported goods to avoid long-distance transportation damage and seawater erosion during shipping.

Our products are packaged in the following ways

Air Bubble Film

Pallet Packaging

Wooden Case

Carton Box

Installation of AS/RS

This is the AS/RS project we did in Tondo, Manila, Philippines in 2020, covering a total area of 7500 square meters, with a height of 25 meters, a total number of 34,256 pallets and a total cost of $400,000+