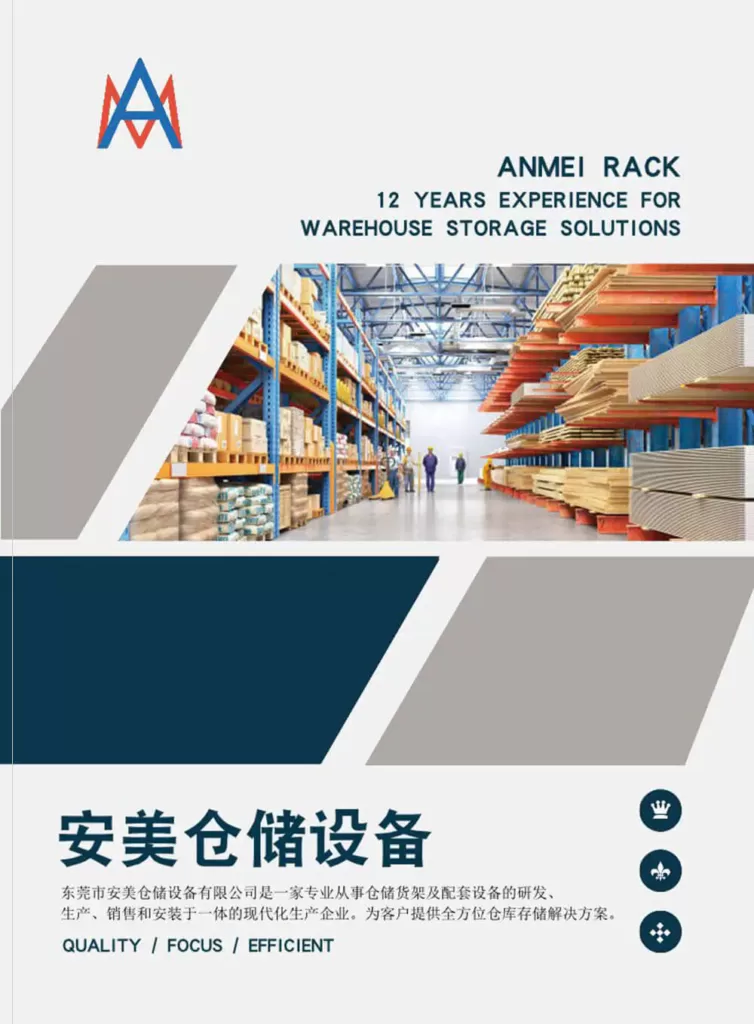

boltless rack or light duty rack

light duty rack or boltless rack are the most widely used type of racks, and they can be used wherever there is something that needs to be stored.In warehouses, retail backrooms, offices, garages, and even homes, one of the most commonly used storage solutions is light duty racking (also known as light-duty shelving or boltless rivet racking). Despite the word “light,” these systems are remarkably versatile and form the backbone of countless small-to-medium storage applications worldwide.

Easy to install.in stock, cheap, the size, the load-bearing capacity, the color, the layers can be customized according to your needs.The common colors for light duty rack or boltless rack are blue, white and red. The most important thing for light duty rack or boltless rack is that Support retail and wholesale.

Additional information

| Standard Size(L*D*H) | 2000*600*2000mm, 2000*600*2500mm, Customizable |

|---|---|

| Layer | 3layer, 4layer, 5layer, 6layer, Customizable |

| Load Capacity | 200KG, 300KG, 500KG, Customizable |

| Color | Blue, Customizable, Gray, Orange |

| Weight | 39.85kg/set |

| Volume | 0.35CBM/sets |

| MOQ | 20 sets |

| Estimated Delivery Time | 5 days |

Free design drawings for you

Layout plan

Three-dimensional view

Renderings

The main production process of boltless rack or light duty rack

1

Punching Process

Punches run the length of the hanging plate at standard intervals where the cross beams are connected, most of them are 50mm or 75mm pitch.

2

Rolling Process

Steel coil through the rolling equipment to form the upright and beam, beam usually have P beam and interlock beam, upright usually have diamond hole and teardrop hole.

3

Welding Process

Through welding, the hanging plate and beam; upright and footplate are closely connected together, which effectively strengthens the stability of the rack structure.

4

Spraying And Baking Process

Polish the product after welding, then use electrostatic powder spraying technology on the surface, and finally use the high-temperature baking process to ensure a smooth surface.

5

Packaging Process

Finally came to the last step. After the production of the product is completed, we usually package the exported goods to avoid long-distance transportation damage and seawater erosion during shipping.

Our products are packaged in the following ways

Air Bubble Film

Pallet Packaging

Wooden Case